Semiconductor Testers

Custom Semi Testers

One-size-fits-all test equipment not meeting your needs? Engineering team out of bandwidth? Talk to us. We'll solve your toughest semiconductor test challenges with innovative, elegant test solutions.

Our team works in concert with yours to create new test solutions aimed not only to fit your specs, but also to achieve your business goals of reducing testing costs, improving yields, and streamlining your testing process.

Product Information

For over 20 years, our custom semiconductor testers have tested billions of semiconductor devices for the world’s largest semiconductor companies. We get it right the first time, so put our expertise to work for you.

A Breadth of Capabilities

A Breadth of Capabilities

We offer turnkey design and manufacturing services to create semiconductor test solutions that excel at meeting your production needs, your test cost requirements, and your ramp cycles. Our integrated team of semiconductor test innovators delivers a complete system tailored to achieve your specific objectives, incorporating:

- Test strategy

- Hardware design

- Software development and integration

- Manufacturing

- Installation

- Program management

- Ongoing support

We are vertically integrated, with electrical design, mechanical design, software design, machine shop, and test engineering all under one roof.

Time-proven processes in program management, supply chain control, configuration management, quality procedures, and testing support delivery of your system on schedule.

Engineer-to-Engineer Collaboration

We work from an “engineer to engineer" philosophy, where our engineering team serves as an extension of yours. We collaborate closely throughout the design process, during system install, and then continue on with support and maintenance.

We work from an “engineer to engineer" philosophy, where our engineering team serves as an extension of yours. We collaborate closely throughout the design process, during system install, and then continue on with support and maintenance.

Your goals are our goals, and this tight collaboration ensures you receive a solution that meets your target of test function, throughput volume, and any other important parameter.

Extensive Semiconductor Industry Experience

Whether you need a design verification system or a production-level tester, we are your experienced partner delivering your systems with the strictest of confidentiality.

We'll work with you to design a system that can test whatever you need for semiconductors, including:

- Devices: application processors, CPUs, baseband processors, memory, board-level modules, end-user whole devices

- Testing types: Functional test, system level test, others

- Technology: mixed-signal, RF, memory, burn-in, high speed interfaces, others

- Packages: single device, SiP, PoP, and more

- Applications: consumer electronics, mobile devices, automotive, IoT, medical, and other industries

A Deep Technology Portfolio

We draw from our extensive technology and engineering expertise to deliver sophisticated, well-engineered solutions that solve complex test challenges. Plus, with world-class program logistics, you can be confident we'll deliver your solution on schedule to meet your critical ship dates. Solutions can range from the simple to the complex, with capabilities to integrate all the resources you need for your system: sophisticated handlers, tester resources, test fixtures, sockets, and software.

We draw from our extensive technology and engineering expertise to deliver sophisticated, well-engineered solutions that solve complex test challenges. Plus, with world-class program logistics, you can be confident we'll deliver your solution on schedule to meet your critical ship dates. Solutions can range from the simple to the complex, with capabilities to integrate all the resources you need for your system: sophisticated handlers, tester resources, test fixtures, sockets, and software.

Services and Support

Together, the synergy of our partnership ensures your success. We offer:

- Engineer-to-engineer collaborative design and support to configure your system

- Dedicated program managers

- A global team supporting installation, training, and maintenance

- Online help and complete documentation for every solution

Reliability Test Systems

With the rise of high-power RF devices, such as Gallium Nitride (GaN) for telecom infrastructure and defense applications, long-duration, massively-parallel reliability testing of these mission-critical chips is more important than ever.

With over 60 years of test industry leadership and innovation, our team of experienced engineers will work directly with yours to design a solution for your reliability test needs.

Product Information

Are you challenged with long test times, pieced-together test equipment, and manual processes, leaving room for error and imposing costly delays in getting your products to market? Count on the deep expertise of the Astronics team to deliver future-proof reliability test for your critical devices.

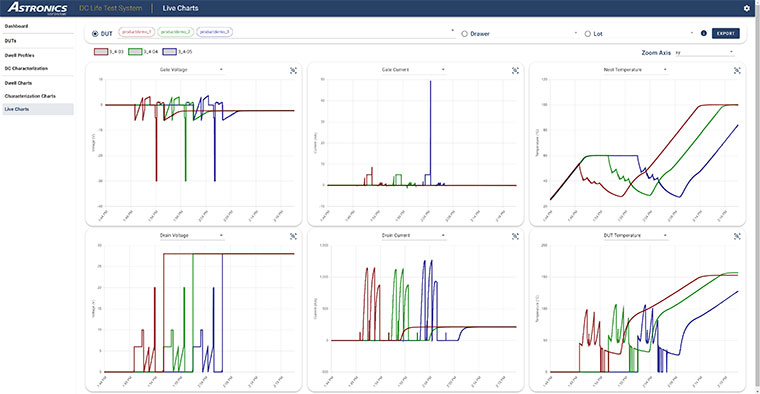

TORCH: Thermally-controlled Operational Reliability Chip Tester

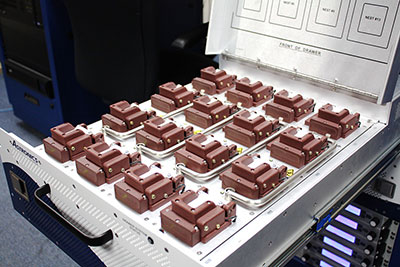

TORCH is a fully-automated, high-throughput, modular test system that can simultaneously test up to 384 sites/DUTs with independent test profiles and parameters. Using accelerated thermal technology, TORCH helps determine the operational life of your device in a fraction of the time. We remove the labor-intensive and time-consuming manual process that is prone to handling faults, and through our state-of-the-art technology, we provide automation that streamlines activities.

TORCH is a fully-automated, high-throughput, modular test system that can simultaneously test up to 384 sites/DUTs with independent test profiles and parameters. Using accelerated thermal technology, TORCH helps determine the operational life of your device in a fraction of the time. We remove the labor-intensive and time-consuming manual process that is prone to handling faults, and through our state-of-the-art technology, we provide automation that streamlines activities.

Experience increased test capacity, reduced testing times, and improved overall reliability of your defense microelectronics with TORCH.

Lighting the Way to Reliable Defense Microelectronics

TORCH offers a variety of test modes and an intuitive graphical user interface that allows quick and easy creation of pre-configured or custom profiles. Highlighted features include:

- In-Situ Dwell Test Modes:

- High-Temperature Operating Life (HTOL)

- Steady-State Life (SSL)

- Step Stress Testing (SST)

- Fully Customizable Profiles

- In-Situ Characterization

- Intuitive profile management, operation, charting, and data logging

- Up to x384 DUTs simultaneously

- Independent control and monitoring of each DUT/ test site

- Independent temperature control of each DUT from ambient to 200°C, +/- 1.0°C

- Air-cooled (no refrigerant required)

Building Blocks Approach

We provide a customizable COTS solution, and our engineer-to-engineer approach ensures the right solution for your test needs by taking into consideration the following building blocks:

We provide a customizable COTS solution, and our engineer-to-engineer approach ensures the right solution for your test needs by taking into consideration the following building blocks:

- Automation options: fully-automatic, semi-automatic, manual

- Measurement science: best practices and innovation

- Additional insertions: based on test strategy and defect mechanisms

- Scalable for your needs: up to four (4) racks

- RF shielded enclosures: for true performance measurement

- User-friendly software: for each of use and data retrieval/archiving

- Tester resources: for both test and operation

- Carrier/ test fixtures: for workflow transport

- Test strategy and plan: to validate device performance and screen defects

- Test methodology

- Cost of test: parallelism and total cost of ownership

- Product life cycle: design for obsolescence

- Maintenance strategy: installation, footprint, and maximizing uptime

- Production plan: labels, serial numbers, traceability, and training

- Open architecture system components

Services and Support

Together, the synergy of our partnership ensures your success. We offer:

- Engineer-to-engineer collaborative design and support to configure your system

- Dedicated program managers

- A global team supporting installation, training, and maintenance

- Online help and complete documentation for every solution

Contact & Support

Astronics Test Systems

Contact & Support

Astronics Test Systems

Contact & Support

Astronics Test Systems

12700 Ingenuity Dr.

Orlando,

FL,

32826

USA

P: +1.407.381.6062 Orlando, FL (HQ)

Request for Quote Customer Support Price List (Update coming soon)Astronics Test Systems

12700 Ingenuity Dr.

Orlando,

FL,

32826

USA

P: +1.407.381.6062 Orlando, FL (HQ)

Request for Quote Customer Support Price List (Update coming soon)