Passenger Service Units

Aerospace Cabin Interiors

Astronics serves commercial applications for Passenger Service Units (PSU), offering vertically-integrated solutions through in-house design, manufacturing, and finishing capabilities. For most PSU programs, Astronics assumes full responsibility for design, development, and qualification of new technologies, including manufacturing and final assembly.

- PSU design, qualification, and manufacture

- Design for manufacturability (DFM)

- Combined product engineering, software engineering, and program management support

- Vertically-integrated manufacturing

- Innovative design technology (e.g. LED lighting) & advanced materials

Product Information

PSU Design & Development

Astronics’ history in aircraft components dates back to the 1960s when it first began providing injection-molded PSUs for the 707 aircraft. Since then, Astronics has produced several PSUs to support The Boeing Company aircraft. In 2008 Astronics was awarded full design responsibility for the 737 Boeing Sky Interior (BSI) PSU. Extensive knowledge of PSU systems and a track record of successful collaboration proved critical to award of this design.

The PSU Project Team exceeded program objectives for reduced cost, reduced weight, and faster delivery. Design for manufacturability, specialized tooling, and close collaboration enabled program success. During collaboration on the 737 BSI PSU, Astronics managed design, qualification, and manufacture of structural, lighting, gasper air, electrical, and acoustic considerations, as well as integration of the oxygen system (with multiple configurations).

Working within strict design constraints, Astronics proposed design elements for the lowest-cost, lightest-weight solution, streamlining manufacturing processes by creating special tooling. Process improvements, made in partnership with The Boeing Company, spurred innovation for the 737 BSI PSU program. That partnership continues today.

Lanyards for AD FAA-2016-9189

Astronics PECO now offers lanyards to satisfy this AD. Learn more.Aerospace Defense Interiors

Astronics serves military applications, offering vertically-integrated solutions through in-house design, manufacturing, and finishing capabilities. For interior defense solutions, our capabilities include:

- Design for manufacturability (DFM)

- Combined product engineering, software engineering, and program management support

- Vertically-integrated manufacturing

- Management, qualification of secondary suppliers

- Materials recommendations

Product Information

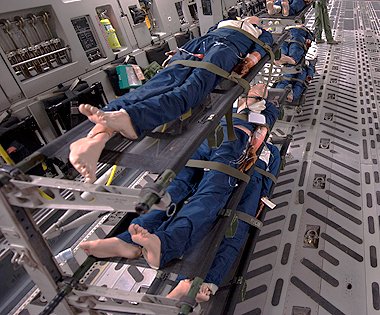

KC-46 Program: Medical Stanchion, Utility Panel

When Boeing Defense Systems (BDS) needed an experienced supplier to meet a tight delivery schedule, Astronics drew upon its core knowledge of commercial aerospace passenger service units and coordinated procurement and delivery. As a result, Astronics was awarded production of the Aero Medical Utility Panel and Medical Stanchion for the KC-46 and C-17 Programs in 2015.

The KC-46 Program represents an opportunity for Astronics to support Boeing Defense Systems (BDS) for military aircraft. In this Program, Astronics assisted in the integration of the KC-46 kits by using data from the C-17, the previous military platform for transport of personnel, cargo, and aeromedical evacuation.

The KC-46 program leverages Astronics’ core competencies in molding, casting, machining, finishing, and assembly. Astronics’ vertically integrated manufacturing reduces the risk of instability in the supply chain. Astronics’ in-house integrated project teams ensure coordinated project management for program success.